Safety

Typical design features

Design concept

The concept used for cylinders designing comprises a set of engineering design principles, in particular:

- acceptably low probability of structural breakup without previous leakage

- predictable resistance of liner structure material to cracking

- feedback providing for termination of the product use in case of through thickness crack leakage

Basic design arrangement

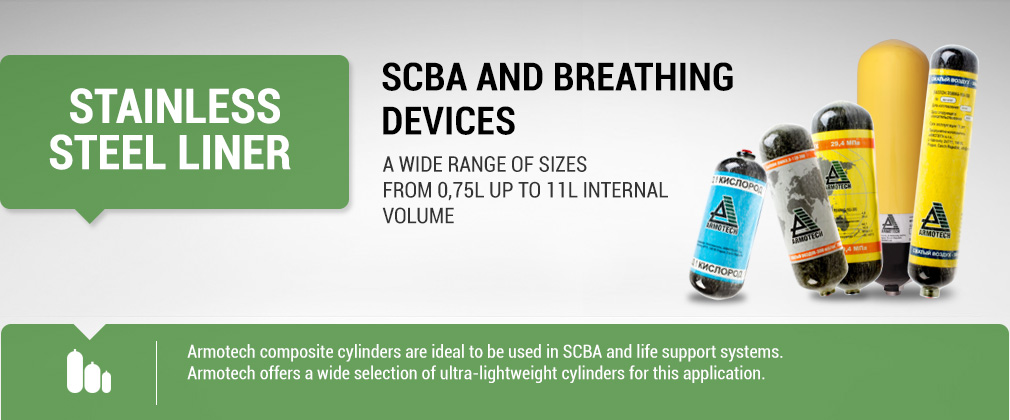

The cylinder basic design arrangement comprises a welded thin liner made of yielding stainless steel and composite overwrapping which covers the whole surface of the liner. Use of corrosion-resistant stainless steel types 304, 304L 316, 316L and so on permits the use of cylinders to store and transport all types of gases and media as per ADR/RID classification.

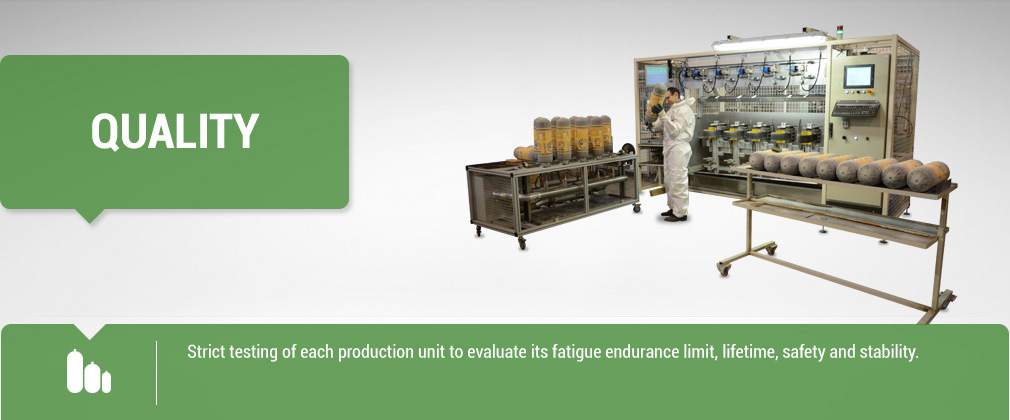

Standart types of product testing:

Standard tests include:

- Limit-load test to evaluate true margins of safety

- Cyclic loading test (at test pressure Ph) to evaluate the period of safe operation.

- Cyclic temperatures test (-60 to +70°C) to evaluate safe operating temperature range.

- Long term sustained load tests (at internal test pressure Ph) at maximum temperature (+80°C).

- Drop test in working conditions from different heights in several versions.

- Test of composite overwrap surface local damage impact on safe operation of the device.

- High-speed impact test with a given energy (gunfire test).

- Test of the cylinder behaviour under fire loading.

- Cyclic pneumatic pressure loading test to evaluate the maximum (minimum) filling levels.

- Permeation test to determine leak tolerance of the gases stored.

- Test of environment impact on safety operation in a specified time interval.